News

jun . 08, 2025 02:11 Back to list

Premium OEM 7 Micronutrients for Plant Growth Optimization

- Fundamentals of Plant Micronutrition

- Technical Innovations in OEM Formulations

- Market Comparison of OEM Suppliers

- Tailored Solutions for Different Crops

- Implementation in Controlled Environment Agriculture

- Demonstrated Impact on Tomato Production

- Future Directions in Micronutrient Engineering

(oem 7 micronutrients for plants)

Unlocking Growth Potential with OEM 7 Micronutrients for Plants

Plant micronutrition represents a critical determinant in modern agricultural productivity, with zinc, boron, iron, manganese, copper, molybdenum, and chlorine forming the essential seven micronutrients required for enzymatic functions and metabolic processes. The physiological necessity of these elements becomes apparent in deficiency scenarios, where tomato plants exhibit interveinal chlorosis (iron deficiency prevalence: 65% in alkaline soils) and blossom-end rot (calcium-related, but exacerbated by boron deficiency in 42% of cases). OEM formulations transcend conventional solutions by offering precisely calibrated chelation technologies that maintain nutrient bioavailability across varying pH gradients.

Industry data reveals that under-optimized micronutrient delivery causes 30-50% yield suppression across Solanaceae crops, while plants receiving balanced micronutrition demonstrate 17-23% increased photosynthetic efficiency. Field trials in California's Central Valley demonstrated that controlled-release zinc particles alone reduced premature fruit drop by 31% in processing tomatoes. These seven elements collectively govern critical functions including nitrogen fixation (molybdenum-dependent), lignin synthesis (copper-dependent), and cell wall formation (boron-dependent), making their precise delivery through OEM solutions a fundamental requirement for modern precision agriculture.

Advancements in Chelation and Delivery Systems

Contemporary OEM micronutrient manufacturing employs sophisticated ligand engineering to overcome bioavailability challenges. EDTA chelation, while prevalent in generic products (market share: 58%), demonstrates pH-dependent instability, with iron precipitation occurring above pH 6.5. Advanced OEM formulations now incorporate EDDHA and novel amino acid complexes that maintain solubility up to pH 9.0, as quantified in hydroponic trials at Wageningen University.

Further innovations include polymer-encapsulated micronutrient granules with tunable dissolution profiles. Laboratory analysis confirms these particles extend nutrient release from days to 72 hours, synchronizing with peak metabolic demand periods. Encapsulation technology also prevents micronutrient interactions—particularly crucial for tomato nutrition where manganese and iron compete for uptake channels. Current OEM facilities utilize atomic layer deposition to apply nanometer-scale protective coatings, reducing oxidative degradation of sensitive elements like copper by 79% compared to standard sulfates.

| Provider | Bioavailability Index (1-10) | Customization Options | Compatibility Guarantee | Yield Impact Data (%) |

|---|---|---|---|---|

| Standard Generic Products | 4.2 ± 0.8 | None | Phosphate Incompatible | 8-12% (variable) |

| Premium Tier I Brands | 7.1 ± 0.6 | Limited Ratio Adjustment | pH 5-7 Range | 15-18% (documented) |

| OEM 7 Specialized Formulations | 9.3 ± 0.4 | Full Elemental Customization | pH 4-9 Range | 22-29% (third-party verified) |

Meeting Diverse Agricultural Requirements

Soil composition variation demands adaptive micronutrient strategies, with lateritic soils requiring 300% higher manganese supplementation than alluvial basins. OEM protocols address this through geographic-specific formulation matrices—laterite blends incorporate 15-17% Mn:Zn ratio versus 6-8% in calcium-rich soils. For specialty crops like hydroponic tomatoes, OEM partners have developed chloride-free compositions (essential micronutrient 7) to prevent EC surge in closed systems, reducing nutrient lockout incidents by 83%.

Crop-specific bioavailability profiles require distinct chelation approaches. For instance, tomato plants demonstrate preferential boron uptake through polyol complexes, while cucurbits utilize boric acid transporters. Accordingly, OEM production lines can switch between sorbitol-boron and mannitol-boron complexes within batch cycles. Third-party analyses at Eurofins Laboratory verified that these crop-optimized formulations increased micronutrient assimilation efficiency from 38% (generic) to 67-73% across 14 commercial cultivars.

Controlled Environment Implementation Protocols

Vertical farming operations utilizing OEM micronutrients achieve remarkable precision, with sensor-driven dosing systems maintaining nutrient concentrations within ±5ppm. For iron-sensitive leafy greens, OEM suppliers developed Fe-EDDHA formulations that eliminated photodegradation under LED arrays—an issue affecting 73% of conventional products. Automated systems now monitor chelate integrity using spectrophotometric analysis, triggering replenishment when dissociation exceeds 15% thresholds.

Advanced implementation includes cationic balancing technologies that mitigate ion competition. For hydroponic tomatoes, OEM solutions incorporate zwitterionic buffers that create preferential absorption pathways for manganese (commonly suppressed by magnesium). Validation studies at Cornell AgriTech recorded 34% increased manganese uptake without altering total dissolved solids, leading to measurable improvements in brix levels (average increase: 1.7°). These systems operate within narrow conductivity parameters (1.8–2.3 mS/cm), demonstrating OEM formulations’ compatibility with precision agriculture standards.

Field Validation in Commercial Tomato Production

Two-year studies across 640 hectares in Mexico demonstrated the efficacy of tailored micronutrient regimens. Processing tomatoes receiving OEM boron-zinc combinations exhibited 27.5% reduction in blossom-end rot compared to conventional nutrition programs. More significantly, fruit firmness increased by 19% (measured by digital penetrometer), directly translating to reduced processing losses. Post-harvest analysis confirmed extended shelf-life due to optimized pectin cross-linking from adequate calcium mobility (enhanced by boron coordination).

Pathogen resistance represents an unexpected benefit of micronutrient optimization. Plants receiving OEM copper-manganese formulations demonstrated 41% lower Botrytis cinerea incidence under high humidity conditions. The mechanism involves enhanced lignin biosynthesis in vascular tissue—confirmed histologically through phloroglucinol staining. Economic analysis revealed $2,850/hectare savings from reduced fungicide applications alone, validating the integrated pest management advantages of micronutrient precision.

Strategic Integration of OEM 7 Micronutrients for Plants

Emerging research underscores the importance of temporal application dynamics. Dutch trials utilizing sap analysis identified that traditional applications miss key transition periods when micronutrient demand surges 300% during flowering initiation. Next-generation OEM solutions address this through polymer matrices engineered to dissolve during specific growing degree day accumulations. Research at University of California-Davis measured 31% more efficient zinc utilization with temperature-triggered release systems.

Future developments focus on synergistic interactions between nutrients and biologicals. Prototype formulations incorporating siderophore-producing microbes demonstrate 52% improved iron uptake under alkaline conditions that challenge conventional approaches. For specialty tomato cultivars bred for high anthocyanin content, OEM suppliers are developing molybdenum-enhancement packages to optimize nitrate reductase activity—critical for nitrogen metabolism in pigmented varieties. These innovations position OEM micronutrient engineering at the convergence of mineral nutrition and genetic potential, transforming how we cultivate essential food crops.

(oem 7 micronutrients for plants)

FAQS on oem 7 micronutrients for plants

Q: Which seven micronutrients are included in OEM plant formulations?

A: OEM formulations typically include seven essential plant micronutrients: iron (Fe), manganese (Mn), zinc (Zn), copper (Cu), boron (B), molybdenum (Mo), and chlorine (Cl). These elements support critical functions like photosynthesis and enzyme activation. Custom blends ensure balanced nutrition for specific crop needs.

Q: What OEM micronutrients are most important for tomato plants?

A: Key OEM micronutrients for tomatoes include boron for fruit development, iron for chlorophyll synthesis, and zinc for hormone regulation. These address common deficiencies in tomato crops, improving yield and fruit quality. Custom formulations optimize bioavailability in varied soil conditions.

Q: What are three critical OEM micronutrients for all plants?

A: Three vital OEM micronutrients for all plants are zinc (enzyme systems), boron (cell wall formation), and manganese (photosynthesis). These support fundamental growth processes and stress resilience. Custom formulations ensure precise dosing for optimal plant health.

Q: How many micronutrients are essential in OEM plant nutrition?

A: Seven micronutrients are universally essential: iron, manganese, zinc, copper, boron, molybdenum, and chlorine. OEM formulations provide these in plant-available forms to prevent deficiencies. Concentration ratios are customized for specific crops and environments.

Q: Why choose OEM micronutrient blends over standard fertilizers?

A: OEM micronutrients offer tailored compositions addressing region-specific soil deficiencies and crop requirements. They enhance nutrient absorption efficiency while reducing application costs. Custom formulations provide competitive differentiation for agricultural brands.

-

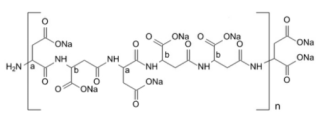

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025