News

ਦਸੰ. . 19, 2024 14:33 Back to list

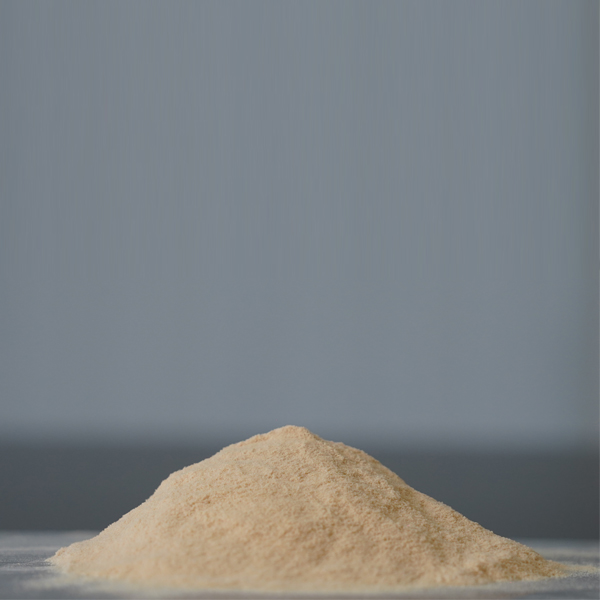

CE Certification for Calcium Sulfate Binder Retarder Solutions and Applications

CE Certification for Retarders in Calcium Sulfate Binders

In the construction and building industry, the role of additives in improving the performance of materials cannot be overstated. One such essential additive is the retarder, particularly in the context of calcium sulfate binders, commonly found in products like gypsum. Understanding the importance of CE certification for these retarders is crucial for ensuring safety, compliance, and quality in construction projects across Europe.

Calcium sulfate, primarily in the form of gypsum, is widely utilized in construction for its excellent properties, including good fire resistance, thermal insulation, and soundproofing capabilities. However, the setting time of gypsum can be quite rapid, which can pose challenges during application, particularly in complex projects that require extended working times. This is where retarders come into play.

Retarders are chemical additives that slow down the hydration process of calcium sulfate, allowing more time for handling and placement before the material sets. This attribute not only enhances workability but also improves the overall quality of the finished product. Without retarders, workers may face difficulty in achieving uniform application, leading to potential structural weaknesses and associated costs in repair or remediation.

Importance of CE Certification

The European Union (EU) has established a regulatory framework for construction products, mandating that specific materials and additives, including retarders for calcium sulfate binders, be CE certified. CE certification indicates compliance with European standards, ensuring that products meet safety, health, and environmental requirements.

1. Quality Assurance CE certification provides assurance that the retarder has been tested and conforms to established standards of quality. This helps manufacturers to gain trust among consumers and contractors, as they can be confident in the performance of the product.

2. Safety Standards The certification process evaluates the safety of the chemicals used in retarders. By adhering to stringent safety protocols, manufacturers can mitigate risks associated with the use of hazardous substances, thereby safeguarding construction workers and end-users.

3. Market Access In the EU, products that are not CE certified cannot be legally marketed or sold. This compliance is crucial for manufacturers looking to expand their market reach. CE certification opens doors for products to be utilized in various projects across Europe.

ce certification retarder for calcium sulfate binder

4. Environmental Protection CE certification also takes into account the environmental impact of products. It promotes the development and use of environmentally friendly retarders, encouraging sustainability in the construction industry.

Choosing a CE Certified Retarder

When selecting a retarder for calcium sulfate binders, it is crucial for designers, engineers, and contractors to ensure they are using a CE certified product. Here are some factors to consider

- Certificates and Documentation Always request and verify the CE certification documents for the retarder. Details such as the intended use and compliance with specific European standards should be clearly stated.

- Supplier Reputation Partnering with suppliers known for their commitment to quality and compliance can provide added confidence in the products being used in construction projects.

- Performance Characteristics Evaluate the performance characteristics of the retarder, such as the extent of retardation, impact on compressive strength, and workability. Ensuring these properties align with project requirements is essential.

- Technical Support A reputable supplier should offer technical support to help in application and troubleshooting, which is invaluable when integrating new materials into construction processes.

Conclusion

The use of retarders in calcium sulfate binders is integral to ensuring effective application and performance in construction. CE certification serves as a crucial indicator of quality, safety, and environmental responsibility, fostering confidence among manufacturers, suppliers, and consumers alike. By choosing CE certified retarders, stakeholders in the construction industry can contribute to more efficient, durable, and sustainable building practices across Europe.

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025