News

ਦਸੰ. . 15, 2024 15:00 Back to list

glyphosate chelator factory

Understanding Glyphosate Chelators and Their Production

Glyphosate, a widely used herbicide, has been at the center of significant agricultural and environmental discussions for decades. As concerns about glyphosate's potential impacts on human health and ecosystems grow, scientists and manufacturers are exploring various methods for soil remediation and crop protection. One of the promising approaches involves the use of chelators—substances that can bind to glyphosate, potentially reducing its phytotoxicity and enhancing soil and crop health. This article delves into the role of glyphosate chelators and the factories producing them.

The Role of Glyphosate Chelators

Chelators are compounds that form stable complexes with metal ions or other substances, leading to their immobilization or reduction in bioactivity. In the case of glyphosate, chelators can bind to this herbicide, minimizing its availability to plants and microorganisms. This can be particularly beneficial in mitigating the negative effects of glyphosate residues in agricultural soils, which may interfere with plant growth or harm beneficial soil organisms.

The mechanism of chelation involves the formation of a ring structure around the glyphosate molecule, effectively isolating it from interaction with other substrates. This process can potentially allow for a more sustainable management of glyphosate in agricultural practices, enabling farmers to utilize the herbicide while minimizing its adverse effects on crop yields and soil health.

Production of Glyphosate Chelators

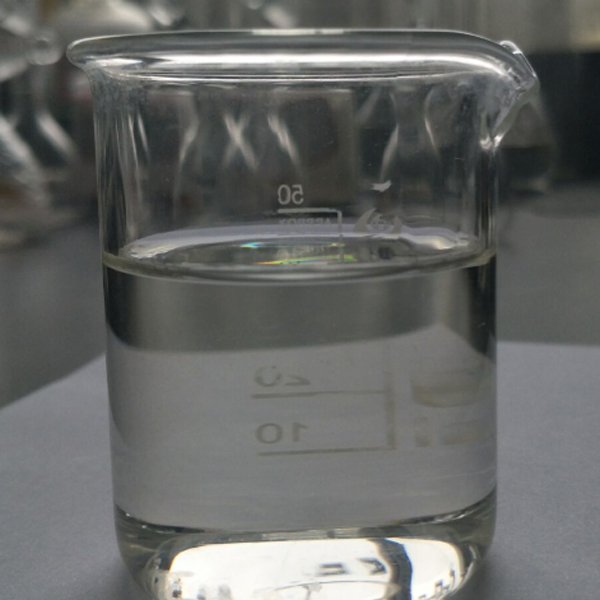

The production of glyphosate chelators occurs in specialized factories equipped with advanced chemical synthesis technologies. These facilities focus on the research and development of novel chelating agents tailored for glyphosate remediation. The production process typically involves a series of chemical reactions, where suitable raw materials are transformed into chelators through carefully controlled conditions.

1. Raw Material Selection Factories source high-quality raw materials that can be used to synthesize effective chelating agents. These may include organic acids, amino acids, and other complexing agents known for their capacity to bind with specific targets, such as glyphosate.

glyphosate chelator factory

2. Synthesis Process The synthesis often requires well-defined reaction pathways that include mixing, heating, and catalytic processes. Skilled chemists are essential during this phase to ensure that the resulting chelator meets the desired performance criteria. Parameters such as temperature, pressure, and pH are meticulously monitored to optimize yield and purity.

3. Quality Control After synthesis, the chelators undergo rigorous quality testing. This ensures that they are effective in binding glyphosate and are safe for the environment. Analytical techniques such as high-performance liquid chromatography (HPLC) and mass spectrometry are often employed to determine the chemical composition and efficacy of the products.

4. Packaging and Distribution Once quality assurance processes are completed, the glyphosate chelators are packaged in suitable containers for distribution. Factories may also offer bulk options for agricultural suppliers, emphasizing the importance of proper labeling and instructions for use to ensure safety and efficacy.

Environmental and Agricultural Implications

The emergence of glyphosate chelators represents a significant advancement in sustainable agricultural practices. By aiding in the detoxification of glyphosate residues, these agents can improve soil health, promote biodiversity, and enhance crop productivity. Farmers using these products can mitigate the risks associated with glyphosate application, thus contributing to more responsible herbicide management.

The production of glyphosate chelators also aligns with a growing global emphasis on reducing chemical inputs in agriculture. As regulatory bodies increase restrictions on chemical herbicides, the development of chelators offers a viable alternative that allows for the continued use of glyphosate in a more controlled manner.

Conclusion

Glyphosate chelators hold great promise in the realm of agriculture, providing a pathway to alleviate the concerns surrounding glyphosate use. The factories producing these innovative compounds play a crucial role in ensuring safe and effective alternatives for farmers. As research continues and technologies advance, the integration of chelators into agriculture could enhance sustainable practices and contribute to the health of ecosystems worldwide.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025