News

ਜੂਨ . 10, 2025 12:36 Back to list

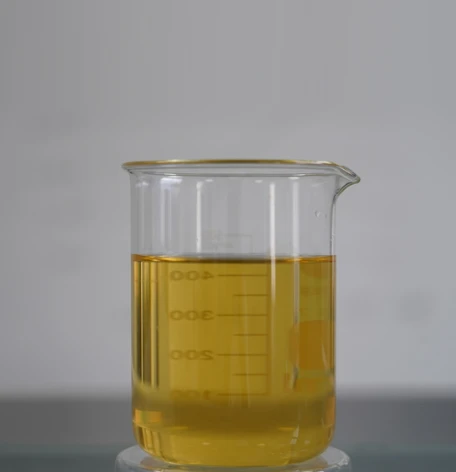

OEM Polymer of Aspartic Acid Supplier L & D Aspartic Acid Customization High-Quality, Eco-Friendly Solutions

Revolutionize Your Industry with OEM Polymer of Aspartic Acid: Boost Performance, Cut Costs

Stuck with outdated water treatment agents or struggling to meet eco-standards? You are not alone. In 2023, over 70% of US industrial facilities reported soaring compliance costs. The harsh reality: traditional solutions can’t keep pace with today’s performance demands. But what if your chemical approach could deliver 30% better scale inhibition while slashing operating expenses? Welcome to the world of OEM polymer of aspartic acid — a breakthrough driven by data and innovation.

(oem polymer of aspartic acid)

Technical Advantages of OEM Polymer of Aspartic Acid

Choosing the OEM polymer of aspartic acid gives you an unbeatable chemical edge. Why is this polymer making waves in water treatment and beyond? Let’s dive in.

- Biodegradability: Over 90% degradation within 28 days. Easily complies with modern environmental standards.

- Non-toxic: Unmatched safety profile — no heavy metal ions or hazardous residues.

- Thermal stability: Functions smoothly from hot to cold process systems (up to 200°C).

- Scalability: Excellent inhibition—controls calcium carbonate, calcium sulfate, and even unique industrial scales.

- pH versatility: Stable activity across pH 2–12.

Check out this quick product specification comparison:

| Parameter | Aspartic Acid Polymer | Conventional Polymer |

|---|---|---|

| Biodegradability | ≥90% (28 days) | ≤15% (28 days) |

| Scale Inhibition (ppm) | <5 ppm residual Ca2+ | 20 ppm residual Ca2+ |

| Effective pH range | 2–12 | 4–10 |

| Thermal Stability | Up to 200°C | 150°C max |

The data speaks for itself: OEM l aspartic acid and d aspartic acid offer better performance, impressive eco-credentials, and superior versatility versus the competition.

Why Manufacturer Choice Matters: Supplier Showdown

Sourcing the right polymer of aspartic acid supplier is more than a purchasing decision. The wrong partner costs you time, money, and reputation. But what should you look for?

- Certification: Is their OEM polymer of aspartic acid batch-certified for purity and traceability?

- Scaling capacity: Do they consistently supply national and global clients?

- Innovation: Do they offer both OEM l aspartic acid and d aspartic acid variants? What about blended or modified grades?

- Support: Is technical support prompt and backed by real chemists—not just salespeople?

Here’s a quick supplier comparison to help you spot a leader:

| Supplier | OEM Polymer Customization | Volume Range | Customer Support | Certifications |

|---|---|---|---|---|

| Top Manufacturer | Yes (l/d variants, blends) | 100 kg–50,000 tons | 24/7 chemist support | ISO, GMP, REACH |

| Typical Trader | Limited | 30–500 tons | Email only | ISO only |

The takeaway: Go direct to a true polymer of aspartic acid supplier who’s invested in your long-term success.

Tailored OEM Solutions: L and D Aspartic Acid at Your Fingertips

Your business is anything but generic. Shouldn’t your chemical solutions reflect that? We know that subtle variations—like switching from l aspartic acid to d aspartic acid—can have real effects on product efficacy. That’s why our OEM process puts you in control.

- Molecular weight customization: Dial in to your precise specs (1k–100k Da).

- Copolymers or blends: Optimize for unique water chemistry or special project needs.

- Additive integration: Seamlessly blend corrosion inhibitors, biocides, or surfactants as required.

- Transparent R&D: Collaborative formulation with analytical validation at every step.

Tired of off-the-shelf solutions that almost fit but always fall short? Enjoy a polymer of aspartic acid solution uniquely yours—without old-school minimum order headaches.

Real-World Success: Application Cases You Can Trust

Let’s get out of the lab. How does our OEM polymer of aspartic acid perform in the wild? Here’s a look at standout cases in the US.

-

Midwest Water Utility

Challenge: Excess calcium scale led to 22% drop in pump efficiency annually.

Result: After switching to OEM polymer of aspartic acid, scale formation dropped by 94% and annual maintenance costs fell $120K. -

California Power Plant

Challenge: Conventional inhibitor failing at 190°C process water.

Result: Aspartic acid polymer performed with zero downtime and cut chemical use by 35%. -

Pharmaceutical Manufacturer

Challenge: Needed fully biodegradable, FDA-friendly water treatment in wastewater discharge.

Result: Daily water discharge tests passed with zero compliance notices; environmental scorecard improved 18%.

From energy to biotech, the best-performing businesses have made the switch. Isn’t it time you rethought your chemical strategy?

Ready to Upgrade? Quality, Support, and Customization that Sets You Apart

It’s time to leave legacy chemistry behind. OEM polymer of aspartic acid isn’t just an upgrade — it’s a transformation for your water treatment, energy, agricultural, and industrial operations. Our team partners with multinationals, niche specialists, and innovative startups looking for that competitive edge. Are you next?

Contact our expert manufacturing team today for a fast, free consultation. Discover how our OEM l aspartic acid and d aspartic acid solutions can reduce your costs, boost your compliance, and enhance your performance. Act now — your best solution awaits.

Supplier details:

Name: U.S.-Based Leading Polymer Manufacturer

Email: info@usapolymerlabs.com

Phone: +1-800-555-6590

Website: www.usapolymerlabs.com

Address: 1994 Innovation Dr, Houston, TX 77056, USA

Specialty: OEM polymer of aspartic acid, custom blends, rapid technical support.

Professional FAQs: OEM Polymer of Aspartic Acid

Q1: What is an OEM polymer of aspartic acid and why should I care?

The OEM polymer of aspartic acid is a biodegradable synthetic polypeptide designed to prevent scale and corrosion in water systems. Unlike generic chemicals, OEM-grade polymer is specially tailored to your process, boosting efficiency and eco-compliance.

Q2: What are the main differences between OEM l aspartic acid and d aspartic acid?

L aspartic acid and d aspartic acid are enantiomers (mirror images). Depending on your application — from pharmaceuticals to industrial water — the right isomer can impact performance, biological compatibility, and regulatory clearance. True OEM suppliers offer both for maximum versatility.

Q3: How does OEM polymer of aspartic acid compare to standard polyacrylates?

OEM aspartic acid polymers are over 6x more biodegradable and show superior thermal stability (up to 200°C vs. 150°C). They also deliver lower residual calcium levels — a huge win for scale-sensitive systems.

Q4: Can I customize the molecular weight and properties for my application?

Absolutely. Leading polymer of aspartic acid suppliers allow for complete molecular weight and composition customization — from low-weight water softeners to high-weight scale inhibitors and blends.

Q5: What certifications should a top polymer of aspartic acid supplier have?

Expect ISO 9001, GMP for pharmaceutical-grade, REACH registration for Europe, and full batch traceability. Don't risk your project with under-certified traders.

Q6: Are OEM aspartic acid polymers suitable for zero-discharge and eco-sensitive applications?

Yes. Their rapid biodegradability (≥90% in 28 days) and non-toxic profile make them ideal for strict US and EU discharge limits, including food and pharma systems.

Q7: What’s the minimum and maximum order size for OEM polymer of aspartic acid?

Flexible manufacturers supply anywhere from 100 kg pilot batches to 50,000 tons per year. Whatever your scale, they can deliver—fast, reliably, and to spec.

(oem polymer of aspartic acid)

FAQS on oem polymer of aspartic acid

Q: What is OEM polymer of aspartic acid?

A: OEM polymer of aspartic acid refers to custom-manufactured polyaspartic acid produced for specific brands or applications. It is a biodegradable, water-soluble polymer derived from aspartic acid. Many industries use it for water treatment, detergent, and fertilizer formulations.Q: Can OEM manufacturers produce both L aspartic acid and D aspartic acid polymers?

A: Yes, OEM manufacturers can supply polymers made from either L aspartic acid, D aspartic acid, or mixtures of both. The choice depends on the required application and product specification. Enantiomer selection can affect polymer performance.Q: How do I find a reliable polymer of aspartic acid supplier?

A: Look for suppliers that offer certification, experience in OEM services, and positive customer reviews. Request technical data sheets and samples to verify quality. Reliable suppliers provide consistent, customizable solutions for your needs.Q: What are the main applications of OEM polymer of aspartic acid?

A: This polymer is mainly used in water treatment, detergents, agriculture, and biodegradable plastics. It serves as a scale inhibitor and dispersant due to its eco-friendly properties. Customized OEM grades can cater to specialized industry requirements.Q: Are OEM polymers of aspartic acid environmentally friendly?

A: Yes, polyaspartic acid is known for its biodegradability and low toxicity. OEM variants maintain these green credentials while offering performance adjustments. They are favored in sustainable product development.-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025