News

aug. . 14, 2024 07:04 Back to list

Factors Influencing the Cost of Custom Polyaspartic Acid for Various Applications and Industries

The Cost Dynamics of Custom Polyaspartic Acid

Polyaspartic acid, a derivative of aspartic acid, has garnered attention in various industries due to its versatile properties, including excellent adhesion, corrosion resistance, and environmental friendliness. Particularly in coatings, adhesives, and sealants, custom formulations of polyaspartic acid are being increasingly sought after. Understanding the cost implications of these customized solutions is crucial for manufacturers, suppliers, and end-users alike.

Factors Influencing the Cost

1. Raw Material Costs The primary ingredient for polyaspartic acid is aspartic acid, which can vary in price based on market demand and availability. Also, the sourcing of other chemical components required for customization can affect overall costs. Fluctuations in agricultural yields and geopolitical factors can impact the supply chain, hence altering the price.

2. Customization Level The degree to which a formulation is customized greatly influences its price. Simple modifications may incur minimal additional costs, while complex, tailored solutions requiring advanced technology or unique additives can significantly increase expenses. The specificity of the required performance characteristics—like UV stability, flexibility, or resistance to chemicals—will also dictate cost variations.

3. Production Scale Economies of scale play an essential role in determining the cost of custom polyaspartic acid. Larger production runs can diminish per-unit costs due to the more efficient use of resources and better utilization of manufacturing capabilities. Conversely, small batches may result in higher costs due to increased labor and setup expenses relative to volume.

4. Regulatory Compliance and Testing The chemical industry is highly regulated, and custom formulations may need to comply with various local, national, and international regulations. Ensuring compliance often requires extensive testing, quality control, and documentation, which can increase costs substantially. Moreover, meeting safety and environmental standards may necessitate additional investments in technology or processes.

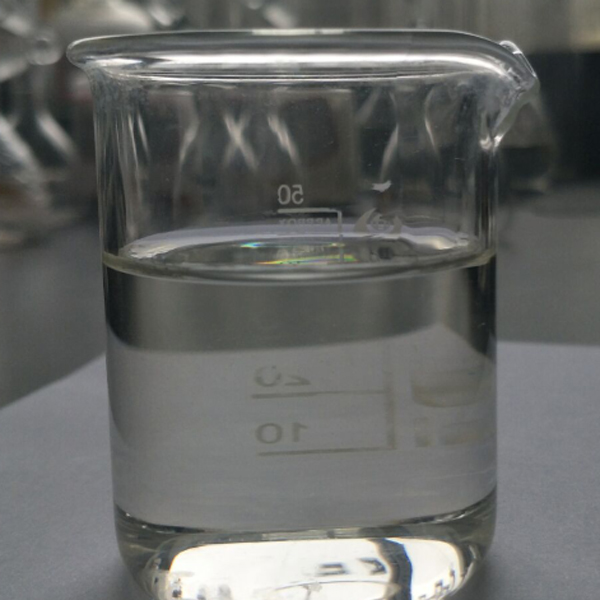

custom polyaspartic acid cost

5. Market Demand The demand for custom polyaspartic acid formulations is on the rise, particularly in the construction, automotive, and aerospace industries due to its superior characteristics compared to traditional polymers. This growing demand can lead to price fluctuations based on market dynamics, where supply struggles to meet the increasing need.

Cost-Benefit Analysis

While the upfront costs of custom polyaspartic acid may be higher than standard formulations, it is essential to conduct a cost-benefit analysis. The long-term advantages of custom solutions often outweigh initial expenses. For instance, their durability and versatility can lead to lower maintenance costs, enhanced product lifespans, and better performance, contributing to overall savings.

Moreover, as industries progressively embrace sustainability, opting for environmentally friendly materials like polyaspartic acid can enhance corporate responsibility profiles. Companies focusing on green technologies may find that the investment in custom formulations aligns not only with their operational needs but also with their brand values.

Conclusion

The cost of custom polyaspartic acid is influenced by a myriad of factors encompassing material costs, degrees of customization, economies of scale, regulatory requirements, and prevailing market conditions. While the initial investment may appear daunting, the benefits—both economic and environmental—often justify the expense. As industries evolve, the demand for tailored, high-performance solutions will likely grow, compelling manufacturers and suppliers to innovate while remaining conscious of cost implications. In this evolving market, understanding the nuances of pricing will be key to making informed decisions that drive success in the competitive landscape.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025