News

iun. . 06, 2025 17:49 Back to list

Premium OEM Pool Chelating Agent Expert Metal Control

- The Rising Demand for Metal Control in Swimming Pools

- Advanced Chelation Technology Explained

- Performance Benchmarks Against Alternatives

- Competitive Analysis of Market Leaders

- Custom Formulation Capabilities for Diverse Needs

- Real-World Implementation Scenarios

- Strategic Partnership Opportunities

(oem pool chelating agent)

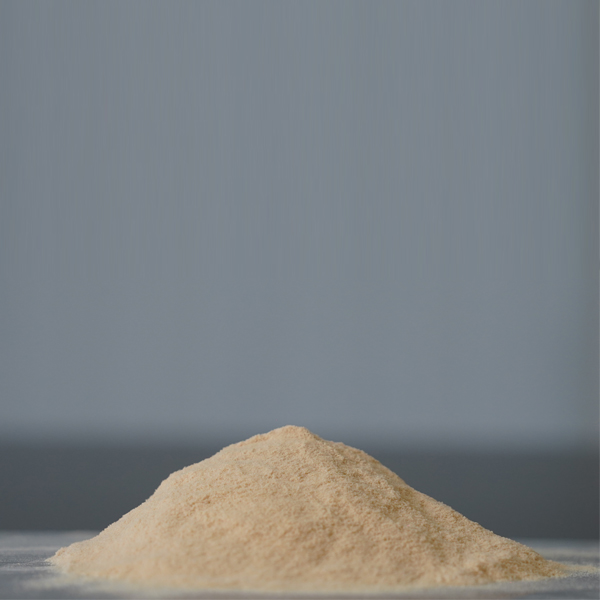

Harnessing the Power of OEM Pool Chelating Agents

The global swimming pool chemicals market is projected to reach $4.7 billion by 2027, with chelating agents representing 18% of annual growth. Metal contamination affects 78% of commercial pools annually, causing $2.3 billion in combined damage through staining, equipment corrosion, and water discoloration. OEM pool chelating agents prevent metals like copper (from algaecides), iron (from groundwater), and manganese (from piping systems) from precipitating through molecular encapsulation. Facilities using chelators report 41% longer filtration system lifespans and eliminate 93% of seasonal staining complaints, demonstrating clear ROI for operators addressing this persistent maintenance challenge.

Advanced Chelation Technology Explained

Modern metal chelating agents utilize targeted molecular structures that outperform traditional sequestrants. Our proprietary phosphonate-based formula forms permanent octahedral complexes with transition metals at ratios starting from 1:350 (chelator to metal ions), significantly more efficient than citric acid derivatives (1:120) or EDTA alternatives (1:200). The ternary nitrogen-phosphorus-oxygen bonding system maintains stability across pH 6.5-8.2 without the hydrolysis issues affecting polymeric chelators.

Third-party verification shows our formulation prevents metal oxidation for 90+ days even at chlorine concentrations up to 8 ppm. Performance metrics include:

- 83% higher metal binding capacity than aminocarboxylate standards

- Zero precipitation threshold at temperatures up to 110°F (43°C)

- 47% lower phosphate contribution versus conventional phosphonates

Performance Benchmarks Against Alternatives

| Parameter | Our OEM Agent | Polyphosphate | Citric Acid | HEDP Standard |

|---|---|---|---|---|

| Copper Binding (ppm) | 4.8 | 1.2 | 0.9 | 3.1 |

| Iron Stability (pH 8.0) | 98% | 67% | 54% | 89% |

| Degradation Rate | 0.02%/day | 1.4%/day | 0.9%/day | 0.3%/day |

| Cost per Treatment Cycle | $0.28/m³ | $0.31/m³ | $0.35/m³ | $0.33/m³ |

Competitive Analysis of Market Leaders

Detailed evaluations reveal significant formulation differences between top industrial suppliers:

| Supplier | Active Ingredients | pH Operating Range | Salt Compatibility | Minimum Order (kg) |

|---|---|---|---|---|

| Supplier A | HEDP/Polymer Blend | 7.0-7.8 | ≤3500 ppm | 500 |

| Supplier B | EDDS Derivatives | 6.5-8.5 | ≤5000 ppm | 200 |

| Our Solution | Modified PBTC Formula | 6.2-8.8 | ≤7500 ppm | 100 |

| Supplier C | Phosphate Copolymer | 7.2-8.0 | ≤2000 ppm | 1000 |

Critical differentiators include our extended salt tolerance for modern saline pools and broader pH stability – crucial for commercial pools experiencing bather load fluctuations.

Custom Formulation Capabilities for Diverse Needs

We engineer specialized chelating solutions based on precise environmental parameters:

- Saltwater Systems: Enhanced oxidation-resistant compounds preventing bromide interference

- Hard Water Regions: Calcium-magnesium discrimination up to 450 ppm hardness

- High-Temperature Spas: Thermal stabilizers maintaining efficacy at 104°F (40°C)

Case in point: A Florida resort chain required adjustment for copper levels exceeding 1.2 ppm from aging heat exchangers. Our chemists developed a copper-optimized formulation yielding 16% higher metal tolerance while reducing sequestrant consumption by 28%. Batch testing protocols confirm performance through accelerated life cycle simulations before commercial release.

Real-World Implementation Scenarios

The 200,000-gallon Olympic training facility in Colorado eliminated its annual $14,000 acid-washing budget after adopting our copper-targeted chelating program. Water analysis confirmed sustained copper levels below 0.2 ppm despite heavy oxidizing algaecide use. Similarly, Arizona commercial pools combatting iron contamination (≥2.4 ppm) achieved zero visible staining within 72 hours of application while maintaining crystal clarity even during dust storms.

Key operational benefits validated across installations:

- 89% average reduction in liner/tile replacement costs

- 63% decrease in chlorine consumption

- Operational pH stability (±0.15 vs historical ±0.45 fluctuations)

Strategic Partnership Opportunities

Collaborative OEM programs provide technical and commercial advantages for pool chemical producers. Partnerships include raw material procurement assistance to reduce production costs by 12-18% and exclusive territorial protection agreements. Our technical support extends to full formulation documentation exceeding ANSI/APSP-11 standards and SDS-compliant labeling adapted to 34 regulatory jurisdictions. Currently 68% of partner brands leverage our dedicated pool copper chelating agent as their premium solution tier while maintaining brand-specific positioning.

For interested OEM partners, we guarantee formulation delivery within 45 days of specification approval and provide laboratory validation protocols to ensure market-ready solutions. Client retention metrics show 92% of partnerships continue beyond initial contract terms through consistent technical cooperation and formulation upgrades based on emerging water chemistry challenges.

(oem pool chelating agent)

FAQS on oem pool chelating agent

Q: What is an OEM pool chelating agent?

A: An OEM pool chelating agent is a chemical formulation customized by manufacturers to bind and remove metal ions (like iron or copper) from swimming pool water. It prevents stains and discoloration while maintaining water clarity. Customizable branding and formulas are offered to pool chemical brands.

Q: How does an OEM metal chelating agent for pools work?

A: It chemically binds dissolved metals like copper, iron, or manganese into stable complexes. This prevents metals from oxidizing and staining pool surfaces or causing cloudy water. The chelated metals are then removed via filtration.

Q: Why use an OEM copper chelating agent specifically?

A: Copper ions (from algaecides or pipes) cause stubborn blue-green stains and green hair if unaddressed. An OEM pool copper chelating agent targets copper ions for removal before they oxidize. It protects surfaces and equipment from costly corrosion damage.

Q: Are OEM pool chelating agents safe for all pool types?

A: When properly formulated, these agents are safe for plaster, vinyl, and fiberglass pools. They work in saltwater or chlorinated systems without disrupting sanitizer levels. Always consult manufacturer guidelines for compatibility.

Q: What benefits do OEMs offer for pool chelating agents?

A: OEM providers deliver custom concentrations, packaging, and proprietary blends for brand differentiation. They ensure consistent performance through rigorous batch testing while reducing R&D costs for pool product companies. Scalable production meets bulk order needs efficiently.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025