News

дец . 07, 2024 07:54 Back to list

buy polyglutamic acid factory

The Growing Demand for Polyglutamic Acid Exploring Factory Solutions

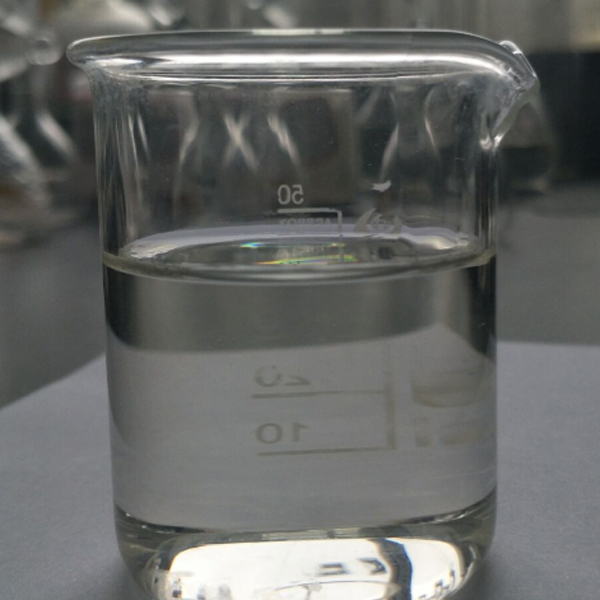

In recent years, the cosmetic and food industries have witnessed a significant rise in the popularity of polyglutamic acid (PGA). This naturally occurring biopolymer, derived from fermented soybeans, is praised for its exceptional moisture-retention properties and skin-boosting benefits. As a result, many companies are looking to capitalize on this trend by establishing factories to meet the growing demand for polyglutamic acid. Let's explore the implications of this surge in interest and what potential buyers should consider when sourcing PGA from factories.

Polyglutamic acid is often touted as a superior alternative to hyaluronic acid, another popular ingredient in skincare formulations. While both compounds serve as powerful humectants, polyglutamic acid is known to hold up to 5,000 times its weight in water, which significantly enhances skin hydration. For manufacturers of beauty products, this feature makes PGA an invaluable ingredient for moisturizers, serums, and masks. Additionally, because it is biodegradable and produced through natural fermentation, it aligns well with the increasing demand for sustainable and eco-friendly products.

Given its versatility, polyglutamic acid is also making waves in the food industry. As a thickening agent and emulsifier, PGA is utilized in various culinary applications, promoting better texture and mouthfeel in sauces, dressings, and dairy products. Manufacturers in this sector are recognizing the benefits of incorporating PGA into their offerings, which has, in turn, increased the need for reliable sources to purchase this ingredient.

The Growing Demand for Polyglutamic Acid Exploring Factory Solutions

1. Quality Control One of the primary concerns for buyers is the quality of polyglutamic acid sourced from factories. It is crucial to ensure that the production processes adhere to stringent quality control standards. Buyers should conduct thorough research on potential suppliers, checking for certifications and reviews that demonstrate their commitment to producing high-quality PGA.

buy polyglutamic acid factory

2. Production Methods The method used to create polyglutamic acid can vary significantly among manufacturers. Fermentation methods are typically preferred, as they align with consumer demand for natural and organic ingredients. Buyers should inquire about the production techniques used by factories and their sourcing of raw materials to ensure strong ethical and sustainability practices.

3. Customization and Versatility Different applications may require specific formulations of polyglutamic acid. Companies should work with factories that offer customization options, allowing for adjustments in molecular weight, concentration, or incorporation of additional active ingredients. This kind of flexibility can greatly enhance a product's marketability.

4. Regulatory Compliance Depending on the country of operation, regulatory standards for cosmetic and food-grade ingredients can vary. It is essential for manufacturers to ensure that their sources of polyglutamic acid comply with local and international regulations. Partnering with factories that have established a reputation for adhering to these standards can protect businesses from potential legal issues.

5. Pricing and Supply Chain As demand fluctuates, pricing for polyglutamic acid may vary across suppliers. Companies should negotiate favorable terms with factory partners while also considering the reliability of the supply chain. A consistent source of quality PGA is essential for maintaining uninterrupted production processes and meeting consumer expectations.

In conclusion, the burgeoning interest in polyglutamic acid presents a unique opportunity for manufacturers in both the cosmetic and food industries. As demand grows, sourcing from reputable factories becomes increasingly important. Quality assurance, sustainable practices, customization options, regulatory compliance, and cost-effectiveness are all critical factors that buyers should consider when looking to purchase polyglutamic acid. By partnering with the right producers, companies can harness the impressive benefits of polyglutamic acid to create innovative products that resonate with today’s conscious consumers.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025