News

нов . 09, 2024 03:29 Back to list

Types of Chelating Agents in OEM Applications and Their Functions

Understanding OEM EDTA Type Chelating Agents

Chelating agents play a crucial role in various industrial and environmental applications by binding metal ions and rendering them inactive. Among the various types of chelating agents, Ethylenediaminetetraacetic acid (EDTA) is one of the most widely used compounds. This article will explore the features, applications, and significance of OEM EDTA type chelating agents, highlighting their role in modern chemistry.

What is EDTA?

EDTA, or Ethylenediaminetetraacetic acid, is a hexadentate ligand that can bind to metal ions through its four carboxylic acid groups and two amine groups. This property enables EDTA to form stable chelate complexes with metals, effectively sequestering them. The structure of EDTA makes it particularly effective in preventing metal ions from reacting in undesired ways, which is vital in various sectors including pharmaceuticals, agriculture, and water treatment.

The Role of Chelating Agents

Chelating agents like EDTA are essential in many chemical processes where metal ions play a crucial role. For instance, in industrial cleaning processes, they help remove metal residues from surfaces, which can otherwise lead to corrosion or degradation of equipment. In agriculture, these agents enhance nutrient availability in the soil, particularly for essential micronutrients such as iron, manganese, and zinc, facilitating better crop yield.

Applications of OEM EDTA Type Chelating Agents

1. Water Treatment One of the primary applications of EDTA and its variations, especially in OEM formulations, lies in water treatment. Chelating agents bind to heavy metals in water, preventing them from causing toxicity and facilitating their removal from wastewater.

2. Agriculture In agricultural practices, EDTA is utilized to enhance the solubility and efficiency of micronutrient fertilizers. By forming stable complexes with metallic nutrients, EDTA ensures that plants can absorb these essential elements, promoting healthier growth and improved yields.

3. Pharmaceuticals and Medicine In the medical field, EDTA is used in chelation therapy, a treatment for heavy metal poisoning. The ability of EDTA to form stable complexes with toxic metals such as lead and mercury helps in their excretion from the body, making it an essential agent in toxicology.

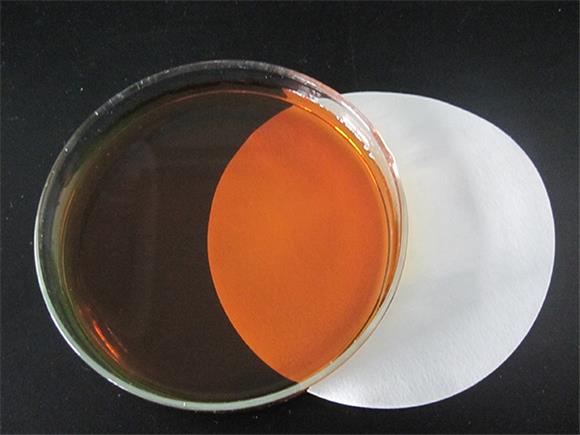

oem edta type chelating agent

4. Industrial Cleaning EDTA is often included in cleaning products to prevent metal ion-induced stains and residues. Its chelating properties help to soften water, making cleaning processes more effective and enhancing the longevity of cleaning equipment.

OEM Considerations

When referring to OEM (Original Equipment Manufacturer) EDTA type chelating agents, it is essential to understand that these products are specifically formulated to meet the needs of particular applications. Manufacturers often customize the concentration, purity, and additional components of EDTA solutions to cater to various industries, ensuring optimal performance in their intended use.

OEM EDTA chelating agents can be tailored to specific environmental conditions or regulatory standards, providing flexibility for manufacturers to incorporate these agents into their processes seamlessly. This customization can significantly improve product efficacy, minimize environmental impact, and ensure compliance with safety regulations.

Environmental Impact and Safety

While EDTA and similar chelating agents are invaluable in many applications, there are also environmental considerations to keep in mind. Certain forms of EDTA can be persistent in the environment, potentially leading to ecological risks, particularly in aquatic systems. Manufacturers and users are increasingly focusing on developing biodegradable alternatives or modifications that reduce the environmental footprint of these chelating agents.

Safety measures must also be adhered to when using EDTA, especially in industrial and agricultural contexts. Proper handling, storage, and disposal procedures should be established to mitigate any hazards associated with exposure to high concentrations of chelating agents.

Conclusion

OEM EDTA type chelating agents represent a cornerstone in various industries, making them indispensable for processes ranging from water treatment to agriculture. Their ability to stabilize metal ions contributes significantly to productivity, safety, and environmental health. As the industry moves toward more sustainable practices, the development and use of biodegradable chelating agents will likely play an essential role in meeting regulatory standards while maintaining performance efficiency. Through continuous innovation, the future of EDTA and other chelating agents remains bright, promising advancements in various applications that benefit both industries and the environment.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025