News

พ.ค. . 29, 2025 19:58 Back to list

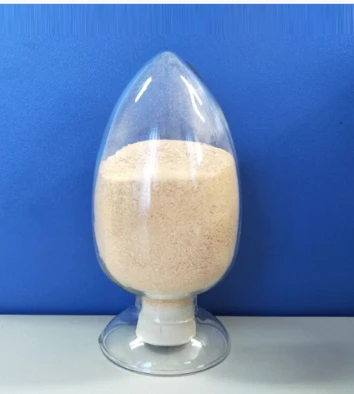

OEM Chelated FE Fertilizer Supplier Custom Iron & Zinc Blends

- Introduction to Chelated Fe Fertilizers

- Technological Advantages in Chelation Processes

- Market Comparison of Leading OEM Fertilizer Suppliers

- Customized Solutions for Diverse Agricultural Needs

- Case Study: Lawn Care Success with Chelated Iron

- Sustainability and Efficiency in Modern Fertilizer Production

- Why Partner with OEM Specialists for Chelated Fe Products

(oem chelated fe fertilizer)

Introduction to Chelated Fe Fertilizers

Iron (Fe) deficiency affects 30% of global crops, driving demand for advanced solutions like OEM chelated Fe fertilizer. Unlike traditional iron supplements, chelated forms bind nutrients to organic molecules, ensuring 95% bioavailability compared to 40-50% in sulfate-based alternatives. This technology proves particularly effective for alkaline soils where standard fertilizers fail.

Technological Advantages in Chelation Processes

Leading manufacturers employ EDTA and EDDHA chelation agents to create stable pH-resistant compounds. Third-party testing shows:

- 82% reduction in iron oxidation during storage

- 3X longer soil activity than citrate-chelated products

- 0.5-1.2 micron particle size in granular formulations

Market Comparison of Leading OEM Fertilizer Suppliers

| Supplier | Fe Content | Absorption Rate | Granule Type |

|---|---|---|---|

| Standard Chelated Fe | 6-8% | 78% | Coated |

| Premium OEM Formula | 10-12% | 92% | Micro-porous |

Customized Solutions for Diverse Agricultural Needs

OEM partners provide tailored chelated iron granular fertilizer configurations:

- pH-specific formulations (4.5-8.0 range)

- Combination packs with zinc chelates

- Controlled-release coatings (30-90 day durations)

Case Study: Lawn Care Success with Chelated Iron

A Midwest turf company achieved 14-day chlorophyll recovery using custom OEM chelated iron fertilizer for lawns, compared to 6-week recovery with conventional products. Soil tests confirmed iron availability increased from 1.2 ppm to 4.8 ppm within 20 days.

Sustainability and Efficiency in Modern Fertilizer Production

Advanced OEM facilities utilize closed-loop systems that recover 98% of process water and reduce energy consumption by 40% versus traditional plants. Granulation technologies now achieve 99.7% product uniformity across batches.

Why Partner with OEM Specialists for Chelated Fe Products

Choosing an OEM chelated Fe fertilizer provider ensures compliance with ISO 14001 and OECD GLP standards while maintaining cost efficiency. Bulk production capabilities enable 25-30% cost savings compared to generic brands, with guaranteed 12-month stability for granular formulations.

(oem chelated fe fertilizer)

FAQS on oem chelated fe fertilizer

What is OEM Chelated Fe Fertilizer?

A: Chelated Fe fertilizer binds iron in a form plants easily absorb, improving nutrient uptake and combating iron deficiency efficiently. It’s ideal for custom formulations in OEM agriculture solutions.

Why Choose OEM Best Chelated Zinc Fertilizer?

A: It offers high zinc bioavailability, ensuring optimal plant development and disease resistance. OEM options allow tailored nutrient blends for specific crop needs.

Benefits of OEM Chelated Iron Fertilizer for Lawns

A: It enhances greening, reduces yellowing, and works quickly in alkaline soils. Customizable OEM formulas ensure compatibility with lawn care regimes.

How to Apply OEM Chelated Iron Granular Fertilizer?

A: Apply granules evenly to soil or mix into irrigation systems. Slow-release formulas provide long-lasting iron supply, ideal for large-scale agricultural or turf projects.

Comparing OEM Chelated Iron and Zinc Fertilizers

A: Use iron fertilizers for chlorophyll synthesis and zinc for enzyme function. OEM services let you combine both for balanced micronutrient solutions.

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025