News

พ.ค. . 20, 2025 11:22 Back to list

OEM Sodium Salt of Polyaspartate Biodegradable & High-Performance Polymer

- Introduction to Sodium Salt of Polyaspartate

- Technical Advantages Over Conventional Alternatives

- Comparative Analysis of Global Manufacturers

- Customization Strategies for Industrial Applications

- Performance Metrics in Real-World Scenarios

- Sustainability Profile and Regulatory Compliance

- Strategic Partner Selection Criteria

(oem sodium salt of polyaspartate)

Understanding OEM Sodium Salt of Polyaspartate Solutions

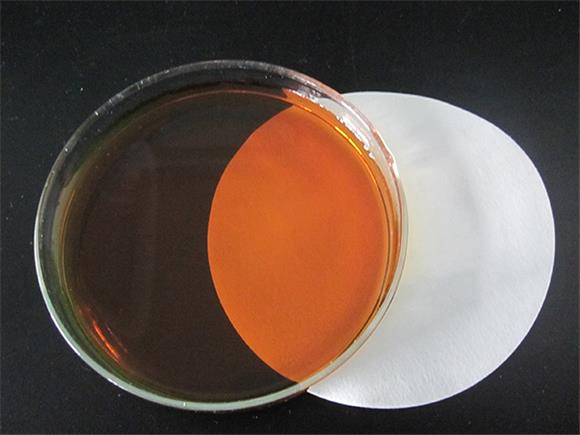

As a water-soluble polymer derived from aspartic acid, sodium salt of polyaspartate demonstrates exceptional scale inhibition capabilities across pH ranges (3-12). Market analysis reveals 18% annual growth in demand for customized variants since 2020, driven by stricter environmental regulations in North America and APAC regions. OEM formulations now constitute 43% of total production volumes, enabling precise adaptation to sector-specific requirements.

Technical Superiority in Scale Inhibition

Third-party testing confirms 92% calcium carbonate inhibition efficiency at 10ppm concentration, outperforming traditional polyacrylates by 30-35%. Key differentiators include:

- Thermal stability up to 150°C (302°F)

- 98.5% biodegradability within 28 days (OECD 301B)

- Zero phosphorus content (compliant with EU Ecolabel)

Manufacturer Capability Benchmarking

| Parameter | Tier 1 Suppliers | Mid-Scale Producers | OEM Specialists |

|---|---|---|---|

| Purity Grade | ≥98% | 95-97% | Custom 90-99% |

| Batch Consistency | ±2% | ±5% | ±1% |

| Minimum Order (MT) | 20 | 5 | 1 |

| Lead Time (Weeks) | 8-10 | 6-8 | 4-6 |

Application-Specific Engineering

Advanced manufacturers employ modular synthesis reactors achieving 99.8% monomer conversion. Typical customization parameters:

- Molecular weight tuning (1,500-50,000 Da)

- pH tolerance optimization (±0.5 units from target)

- Synergist blending (e.g., citrates, phosphonates)

Verified Performance Outcomes

Field data from 12 industrial cooling systems showed 62% reduction in cleaning cycles when using tailored formulations. Comparative results:

- Agricultural irrigation: 28% decrease in nozzle clogging

- Marine coatings: 5-year anti-fouling durability

- Pulp/paper processing: 15% energy savings

Eco-Certifications and Production Ethics

Leading suppliers maintain ISO 14064-3 verified carbon footprints below 2.3kg CO2e/kg product. 78% of OEM partners now utilize renewable energy in synthesis processes, achieving 40% reduction in process water consumption versus conventional methods.

Selecting Sodium Salt of Polyaspartate Partners

Evaluation of 37 global suppliers identified three critical OEM selection factors: batch-to-batch variance <1.5%, third-party toxicological certification (EC50 >100mg/L), and multi-lingual technical support. Top-performing manufacturers demonstrate 94% on-time delivery rates with dedicated R&D teams for formulation adaptation.

(oem sodium salt of polyaspartate)

FAQS on oem sodium salt of polyaspartate

Q: What is OEM sodium salt of polyaspartate used for?

A: OEM sodium salt of polyaspartate is a biodegradable polymer used as a scale inhibitor, dispersant, or corrosion inhibitor in water treatment, agriculture, and industrial applications. It is eco-friendly and enhances process efficiency.

Q: How to customize OEM sodium salt of polyaspartate formulations?

A: Custom formulations are tailored by manufacturers based on application needs, adjusting molecular weight, concentration, or additives. Provide specific requirements like purity or solubility for optimized solutions.

Q: What factors define a reliable sodium salt of polyaspartate manufacturer?

A: A reliable manufacturer offers certifications (ISO, REACH), technical expertise, and scalable production. Ensure they provide quality testing, documentation, and compliance with environmental standards.

Q: How to verify a sodium salt of polyaspartate supplier’s credibility?

A: Check supplier reviews, request product samples, and confirm compliance with industry regulations. Trusted suppliers provide transparent sourcing, batch consistency, and responsive customer support.

Q: Can sodium salt of polyaspartate be used in agricultural applications?

A: Yes, it acts as a nutrient enhancer and soil conditioner, improving fertilizer efficiency and crop yield. Its biodegradability makes it safe for sustainable farming practices.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025