News

พ.ย. . 16, 2024 19:30 Back to list

Calcium Sulfate Binder Retarder Supplier for Enhanced Performance and Durability

The Importance of Retarders in Calcium Sulfate Binder Applications

Calcium sulfate binders, commonly known as gypsum, are widely used in construction and renovation due to their unique properties such as quick setting times, high strength, and ease of handling. However, in certain applications, the rapid setting of these binders can pose challenges. To address this issue, the use of retarders has become increasingly important, allowing for extended workability and ensuring that projects are completed with precision.

Retarders are chemical additives that slow down the setting process of calcium sulfate binders. This is crucial in various conditions, particularly when large surface areas are being covered or when intricate detailing is required. By extending the working time, contractors can manage their processes more effectively, reducing the risk of premature setting and ensuring a high-quality finish.

One of the primary applications for calcium sulfate binders with retarders is in plastering and flooring. In plastering, details such as smooth finishes and intricate moldings demand that the plaster remain workable for a longer period. Without adequate control over setting times, there is a risk of cracks forming due to uneven application or inadequate manipulation of the material while it is still workable.

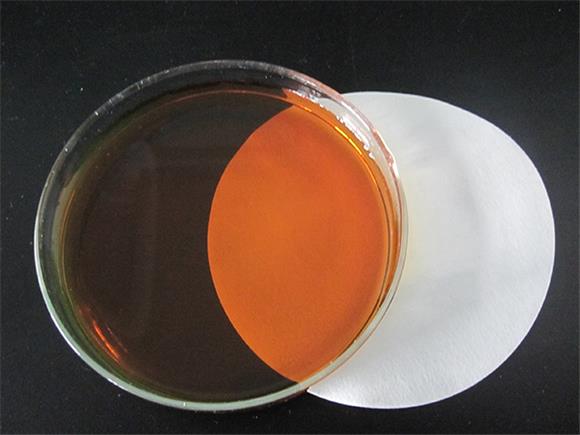

retarder for calcium sulfate binder supplier

In flooring, particularly in large-scale installations, the use of retarders allows layers of gypsum-based products to be spread seamlessly over expansive areas, providing uniformity and strength. This is especially relevant in environments subjected to varying temperatures, where rapid drying could lead to inconsistencies and potential failures.

The choice of retarders is critical, as different projects may require specific characteristics from these additives. For instance, some retarders are derived from natural sources, while others may be synthetically produced to meet stringent performance criteria. Suppliers of calcium sulfate binders need to offer a range of retarder options to cater to the diverse needs of the construction industry.

Moreover, the integration of retarders also aligns with sustainability practices. By allowing for more extended working times, construction teams can minimize waste and avoid the need for rework caused by setting issues. This is increasingly important in an industry that is striving for greener practices, reducing its overall environmental footprint.

In conclusion, the incorporation of retarders into calcium sulfate binder applications plays a significant role in enhancing workability, quality, and sustainability in construction. Choosing the right supplier who understands these dynamics can make a substantial difference in project outcomes, ensuring teams are equipped with the best materials to achieve their goals effectively. As the construction landscape continues to evolve, the demand for high-performance retarders will undoubtedly grow, emphasizing their importance in the future of building practices.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025