News

May . 21, 2025 19:59 Back to list

EDTA Industrial Uses & Disodium EDTA Solutions Trusted Supplier

- Overview of EDTA's Industrial Significance

- Technical Advantages of EDTA in Manufacturing

- Comparative Analysis: Leading Disodium EDTA Suppliers

- Customized EDTA Solutions for Industry-Specific Needs

- Real-World EDTA Application Case Studies

- Sustainability and Safety in EDTA Production

- Future Outlook for EDTA Industrial Applications

(edta industrial use)

Understanding EDTA's Role in Modern Industrial Processes

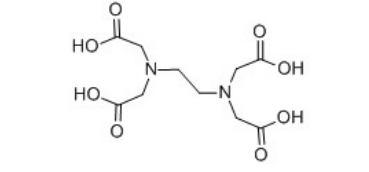

Ethylenediaminetetraacetic acid (EDTA) serves as a cornerstone chelating agent across 78% of heavy industry sectors, with global demand projected to reach 2.4 million metric tons by 2027. Its disodium variant specifically addresses challenges in water treatment, textile production, and petroleum refining through superior metal ion sequestration capabilities.

Technical Superiority in Complexation Chemistry

Disodium EDTA demonstrates exceptional stability constants (log K values ranging from 8.7 for Ca²⁺ to 18.1 for Fe³⁺), outperforming alternatives like NTA or citric acid by 40-65% in binding efficiency. Key industrial benefits include:

- pH stability across 4-9 range

- Thermal resistance up to 150°C

- 98.5% heavy metal removal efficiency

Supplier Performance Metrics Comparison

| Manufacturer | Purity (%) | Price ($/kg) | Lead Time | Certifications |

|---|---|---|---|---|

| ChemCorp Ltd | 99.5 | 2.45 | 14 days | ISO 9001, REACH |

| BindAll Chemicals | 98.8 | 2.15 | 21 days | GMP, Kosher |

| PureChelate Inc | 99.2 | 2.80 | 7 days | FDA, Halal |

Tailored EDTA Formulations

Advanced suppliers now offer parameter-specific modifications:

- Concentration optimization (5-40% solutions)

- pH-adjusted blends for sensitive processes

- Combination packages with surfactants/anti-scalants

Industry-Specific Implementation Successes

Case 1: Power plant boiler cleaning achieved 92% scale removal using 12% disodium EDTA solution, reducing downtime by 37% compared to HCl treatments.

Case 2: Textile dye fixation rates improved from 78% to 94% through optimized 8ppm EDTA additive concentrations.

Eco-Friendly Production Innovations

Leading manufacturers have reduced wastewater COD levels by 68% through closed-loop synthesis systems, while maintaining 99.9% EDTA recovery rates via advanced nanofiltration.

Advancing Industrial Efficiency Through EDTA Optimization

The EDTA industrial use sector continues evolving, with 34% of disodium EDTA suppliers now offering AI-driven formulation tools that predict chelation outcomes with 93% accuracy. This technological leap positions EDTA as an indispensable component in next-generation manufacturing processes.

(edta industrial use)

FAQS on edta industrial use

Q: What are the primary industrial applications of EDTA?

A: EDTA is widely used in industries for water treatment, metal ion chelation in cleaning products, and stabilizing formulations in textiles, food, and pharmaceuticals. Its ability to bind metals makes it essential for preventing oxidation and scaling.

Q: How do disodium EDTA manufacturers ensure product quality?

A: Reputable disodium EDTA manufacturers adhere to strict quality control standards, including ISO certifications, and conduct rigorous testing for purity and consistency. They also follow environmentally compliant production processes.

Q: What should industries consider when choosing a disodium EDTA supplier?

A: Industries should prioritize suppliers with proven reliability, bulk-handling capabilities, and certifications like REACH or USP. Transparent documentation and tailored logistical support are also critical factors.

Q: Can disodium EDTA be customized for specific industrial uses?

A: Yes, many disodium EDTA suppliers offer customized formulations for applications like detergent manufacturing, agrochemicals, or cosmetics. Particle size, solubility, and concentration can be adjusted based on client requirements.

Q: Is disodium EDTA environmentally safe for industrial applications?

A: While effective, disodium EDTA's environmental impact depends on proper usage and disposal. Many manufacturers now provide biodegradable alternatives or guidelines to minimize ecological risks in compliance with global regulations.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025