News

Ara . 04, 2024 11:14 Back to list

OEM Aluminum Chelation Solutions for Enhanced Metal Ion Removal and Environmental Protection

The Role of OEM Aluminum Chelation in Modern Applications

Aluminum is one of the most abundant elements on Earth, finding its way into a multitude of applications, from construction and transportation to packaging and electronics. However, the rising concerns regarding aluminum's potential negative effects on human health and the environment have led to the need for more efficient and safer handling of this metal, particularly in industrial processes. One method that has emerged as a solution is aluminum chelation, particularly in the context of OEM (Original Equipment Manufacturer) practices.

Understanding Aluminum Chelation

Chelation refers to the process by which a chelating agent binds to a metal ion, forming a stable, water-soluble complex. This process is essential for making certain metals more bioavailable and less toxic. In the case of aluminum, chelation can prevent the metal from causing harm within biological systems while facilitating its excretion from the body. Chelating agents can effectively capture aluminum ions, leading to increased safety in products that may have otherwise posed health risks.

Significance in OEM Industries

OEM industries often utilize various metals, including aluminum, in their manufacturing processes. The application of aluminum chelation in these sectors can enhance product safety, improve performance, and mitigate environmental impact. For instance, in the automotive industry, aluminum is widely used due to its lightweight and strength qualities. However, improper handling or residues from manufacturing processes can lead to aluminum leaching into components or even the environment, raising health concerns.

By employing chelation technology, OEM manufacturers can create formulations that minimize aluminum exposure, ensuring that the final products are safer for consumers and compliant with regulations. This approach not only enhances safety but also improves the overall integrity of the product.

Benefits of Aluminum Chelation in OEM Practices

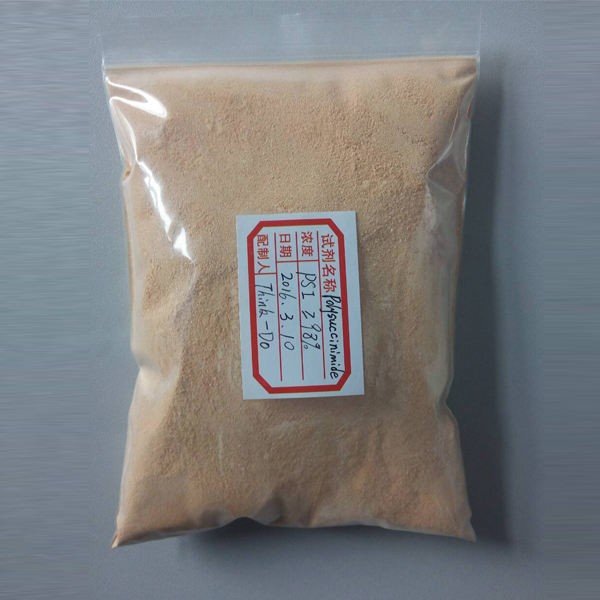

oem aluminum chelation

1. Enhanced Safety By using chelating agents, OEM manufacturers can significantly reduce the risks associated with aluminum exposure. This is particularly important in industries that cater to sensitive populations, such as the food and beverage sector, where products must adhere to stringent safety regulations.

2. Improved Performance The chelation process can improve the stability of aluminum compounds used in various applications, leading to better performance metrics for the end product. This stability translates to longer shelf life and reduced degradation over time, meaning that products maintain their integrity for a longer period.

3. Environmental Considerations Implementing aluminum chelation within OEM processes can also lead to reduced environmental impact. By minimizing the likelihood of aluminum leaching into soil and water systems, manufacturers can play a proactive role in conserving ecosystems and adhering to environmental regulations.

4. Cost Efficiency While there may be an initial investment in developing new chelation strategies and formulations, the long-term savings associated with fewer regulatory penalties, reduced waste, and improved product quality can be significant.

Challenges and Considerations

Despite its many benefits, the integration of aluminum chelation into OEM practices is not without challenges. The selection of appropriate chelating agents is critical; not all agents will effectively bind with aluminum, and some may pose their own health risks. Additionally, manufacturers must navigate the complexities of regulatory compliance as they shift to using chelation technologies.

Conclusion

In summary, the adoption of OEM aluminum chelation strategies represents a forward-thinking approach to improving product safety, performance, and environmental responsibility. As industries continue to evolve and respond to consumer demands for safer and more sustainable products, chelation technology will play an increasingly vital role. By investing in these innovative practices, OEM manufacturers can not only enhance their product offerings but also contribute positively to public health and the environment. The future of aluminum utilization will undoubtedly be shaped by the advancements in chelation technologies, marking a significant step towards safer industrial practices.

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025