News

Okt . 17, 2024 01:21 Back to list

plastretard supplier

Understanding the Role of Plastic Retardant Suppliers

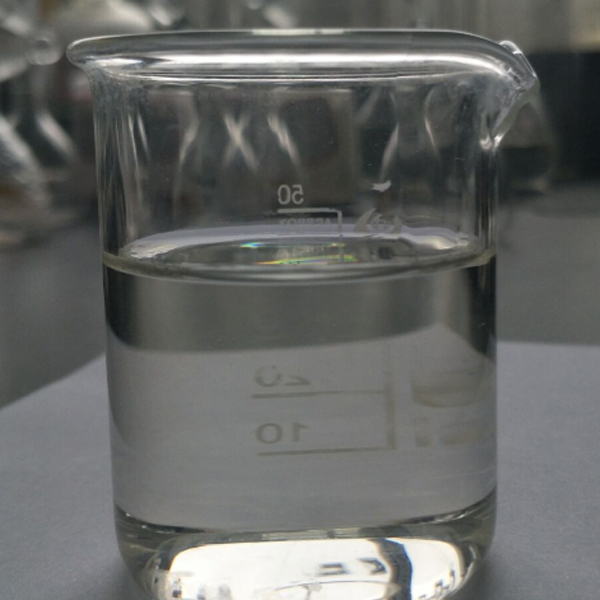

In an ever-evolving industrial landscape, the demand for materials that enhance safety and compliance has reached new heights. Among these materials, plastic retardants—substances that inhibit or delay the ignition or spread of fire in plastics—are crucial for a wide range of applications. This underscores the vital role of plastic retardant suppliers in ensuring product safety and reliability across various sectors.

The Importance of Plastic Retardants

Plastic retardants serve as a key component in manufacturing plastics used in consumer goods, electronics, automotive parts, and construction materials. Given the inherent flammability of most plastics, incorporating retardants is not just beneficial but often mandatory, particularly in sectors where safety is paramount. For instance, in the automotive industry, plastic components must meet stringent fire safety standards to protect passengers in the event of an accident.

As regulations around fire safety become stricter, the demand for effective and environmentally-friendly plastic retardants has surged. Suppliers play a critical role in this landscape by providing innovative products that meet regulatory requirements while ensuring performance effectiveness.

Key Types of Plastic Retardants

Plastic retardants can generally be categorized into two types halogenated and non-halogenated

.- Halogenated Retardants Often derived from compounds containing bromine or chlorine, these retardants are effective at lower concentrations. However, concerns about the environmental and health impacts of halogenated compounds have prompted many industries to seek alternatives.

- Non-Halogenated Retardants These materials, including phosphorus-based compounds and inorganic fillers, are gaining popularity due to their lower environmental footprint and improved safety profiles. They are designed to achieve similar fire retardant properties without the associated toxicity concerns of halogenated agents.

The choice between these types often depends on the end-use application and specific fire safety requirements, making it vital for suppliers to offer a range of options tailored to various industries.

plastretard supplier

Roles of Plastic Retardant Suppliers

1. Innovation and Development Plastic retardant suppliers are at the forefront of developing new formulations that enhance fire resistance without compromising material performance or environmental safety. This is especially crucial as industries continue to pursue sustainable practices.

2. Compliance and Testing Suppliers often assist manufacturers in understanding and complying with various fire safety standards, including UL94, IEC 60332, and ASTM E84. They provide technical documentation and testing services that ensure products meet necessary regulations.

3. Custom Solutions Each industry has unique needs when it comes to fire safety. Suppliers work closely with clients to develop custom solutions that address specific challenges, whether it’s improving the flame resistance of a new polymer blend or enhancing the thermal stability of a product.

4. Education and Support Beyond product supply, reputable plastic retardant suppliers offer valuable educational resources and technical support to help manufacturers understand the best practices for integrating retardants into their processes and improving overall safety.

Challenges Faced by Suppliers

Despite their critical role, plastic retardant suppliers face several challenges. Regulatory pressures are one, as changes in government policies can disrupt production processes and product availability. Additionally, the transition towards sustainable practices requires considerable investment in research and development, which may not yield immediate financial returns.

Furthermore, competition is fierce as manufacturers look for cost-effective alternatives to traditional retardants. Suppliers must not only innovate but also balance cost considerations to remain competitive in a price-sensitive market.

Conclusion

Plastic retardant suppliers play an indispensable role in enhancing the safety and performance of plastic materials in a variety of industries. As regulatory pressure and consumer expectations evolve, these suppliers will continue to innovate and adapt, ensuring that they meet the growing demand for safer and more sustainable fire retardant products. Their commitment to development and compliance not only benefits manufacturers but ultimately safeguards end-users, making a lasting impact in the world of materials science.

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025