News

Okt . 07, 2024 19:55 Back to list

polyaspartic acid cost manufacturer

The Cost Dynamics of Polyaspartic Acid Insights from Manufacturers

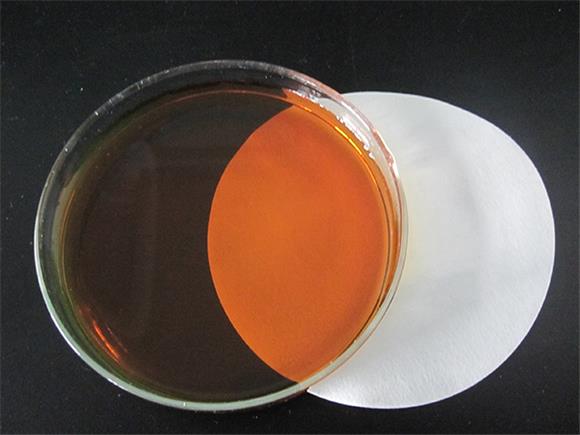

Polyaspartic acid, a versatile polymer derived from aspartic acid, has gained significant attention in various industries, particularly in coatings, adhesives, and as a superabsorbent material. Its unique properties, such as fast curing times, excellent adhesion, and UV resistance, make it a favored choice among manufacturers and end-users alike. However, the cost of polyaspartic acid can greatly influence its adoption across different sectors. Understanding the factors that affect its pricing from manufacturers can provide valuable insights for businesses looking to incorporate this innovative material into their product offerings.

One of the primary factors determining the cost of polyaspartic acid is raw material availability. The key ingredient, aspartic acid, is derived from petrochemical sources or biological processes, making its price susceptible to fluctuations in crude oil prices and changes in supply chain dynamics. Manufacturers often need to navigate these fluctuations to maintain a competitive edge while ensuring that their pricing remains attractive to customers.

The Cost Dynamics of Polyaspartic Acid Insights from Manufacturers

Another important aspect is the scale of production. Larger manufacturers benefit from economies of scale, allowing them to spread fixed costs over a larger volume of output. This can lead to more competitive pricing compared to smaller players in the market. Furthermore, large-scale operations often have established relationships with suppliers, granting them better negotiation power for sourcing raw materials at lower prices.

polyaspartic acid cost manufacturer

Market demand is equally crucial in shaping pricing strategies for polyaspartic acid. As industries such as construction and automotive continue to expand, the demand for high-performance coatings that incorporate polyaspartic acid is expected to rise. Manufacturers often adjust their pricing strategies in response to shifts in demand, creating a dynamic pricing environment that reflects current market conditions.

Additionally, regulatory considerations can impact the cost of polyaspartic acid. Manufacturers must comply with various environmental and safety regulations, which can necessitate investments in compliance measures, additives, and safety features. These additional costs may be passed on to consumers, affecting the overall market pricing of polyaspartic acid.

Finally, regional factors can affect pricing as well. Transportation costs, local regulations, and market saturation in different geographical areas can lead to significant disparities in polyaspartic acid pricing. Manufacturers might find that they need to adapt their pricing strategies depending on the region in which they operate.

In conclusion, the cost of polyaspartic acid from manufacturers is influenced by a myriad of factors, including raw material prices, production methods, economies of scale, market demand, regulatory conditions, and regional considerations. Understanding these elements is vital for businesses looking to source polyaspartic acid effectively and strategically. By keeping abreast of these dynamics, manufacturers and consumers alike can make informed decisions that optimize their supply chain and product offerings in an increasingly competitive marketplace.

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025

-

Best Chelated Iron Supplement for Plants Reliable Chelated Iron Fertilizer Supplier & Price

NewsJul.06,2025