News

Июл . 12, 2024 10:23 Back to list

Cost of producing polyglutamic acid and factors affecting its price fluctuations

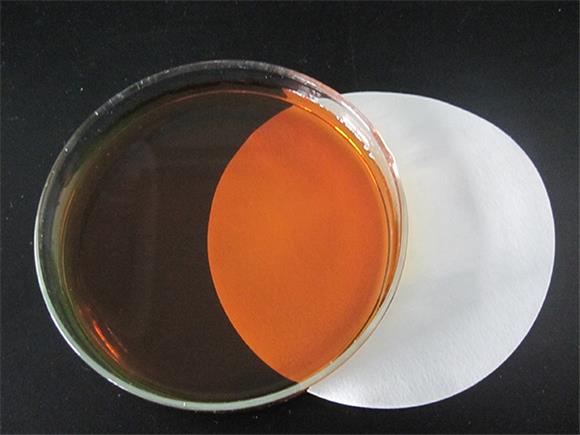

Polyglutamic acid (PGA) is a biodegradable and non-toxic polymer that has gained significant attention due to its various applications in the fields of medicine, agriculture, and cosmetics. PGA is produced through fermentation using microorganisms such as Bacillus subtilis, and the cost of production plays a crucial role in determining its commercial viability.

The production price of PGA is influenced by various factors, including the raw materials used, fermentation process parameters, downstream processing, and purification methods. The most significant cost component in PGA production is the substrate used for fermentation. Common substrates include glucose, soybean meal, and glutamic acid, with glucose being the most widely used due to its cost-effectiveness and availability.

The fermentation process parameters such as pH, temperature, agitation rate, and aeration also play a crucial role in determining the production cost of PGA. Optimal fermentation conditions need to be maintained to ensure high yield and productivity while minimizing production costs. Additionally, downstream processing steps such as cell separation, purification, and drying contribute to the overall cost of PGA production.

In recent years, advancements in bioprocess engineering and genetic engineering have led to significant improvements in PGA production efficiency and cost reduction. Engineering microorganisms for improved PGA production, optimizing fermentation conditions, and developing novel purification techniques have helped in reducing the overall production cost of PGA

polyglutamic acid production price. The market demand for PGA is steadily increasing due to its biocompatibility, biodegradability, and diverse applications. In the medical field, PGA is used in tissue engineering, drug delivery systems, and wound healing due to its biocompatibility and ability to mimic the natural extracellular matrix. In agriculture, PGA is used as a soil conditioner and plant growth promoter to improve crop yield and quality. In the cosmetics industry, PGA is used in skincare products for its moisturizing and anti-aging properties. Despite its numerous potential applications, the high production cost of PGA remains a significant challenge for its widespread commercialization. Research efforts are focused on developing cost-effective production processes, utilizing waste substrates, and improving fermentation techniques to reduce the production cost of PGA. With ongoing advancements in biotechnology and bioprocessing, the production price of PGA is expected to decrease, making it more accessible for various industrial applications. In conclusion, the production price of polyglutamic acid is a critical factor in determining its commercial viability and widespread adoption. By optimizing fermentation processes, utilizing cost-effective substrates, and developing efficient purification methods, the production cost of PGA can be significantly reduced, paving the way for its increased use in medicine, agriculture, and cosmetics.

polyglutamic acid production price. The market demand for PGA is steadily increasing due to its biocompatibility, biodegradability, and diverse applications. In the medical field, PGA is used in tissue engineering, drug delivery systems, and wound healing due to its biocompatibility and ability to mimic the natural extracellular matrix. In agriculture, PGA is used as a soil conditioner and plant growth promoter to improve crop yield and quality. In the cosmetics industry, PGA is used in skincare products for its moisturizing and anti-aging properties. Despite its numerous potential applications, the high production cost of PGA remains a significant challenge for its widespread commercialization. Research efforts are focused on developing cost-effective production processes, utilizing waste substrates, and improving fermentation techniques to reduce the production cost of PGA. With ongoing advancements in biotechnology and bioprocessing, the production price of PGA is expected to decrease, making it more accessible for various industrial applications. In conclusion, the production price of polyglutamic acid is a critical factor in determining its commercial viability and widespread adoption. By optimizing fermentation processes, utilizing cost-effective substrates, and developing efficient purification methods, the production cost of PGA can be significantly reduced, paving the way for its increased use in medicine, agriculture, and cosmetics.

Latest news

-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025