News

Июл . 08, 2025 07:30 Back to list

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

- Introduction to OEM Potassium Chelating Agent

- Technical Advantages of Potassium-Based Chelating Agents

- Comparative Manufacturer Analysis

- Significance of Customization in Potassium Chelating Agents

- Real-World Applications Case Studies

- Future Prospects and Market Trends

- Conclusion: Unlocking Value with OEM Potassium Chelating Agents

(oem potassium chelating agent)

Introduction to OEM Potassium Chelating Agent: Catalyzing Modern Chemical Solutions

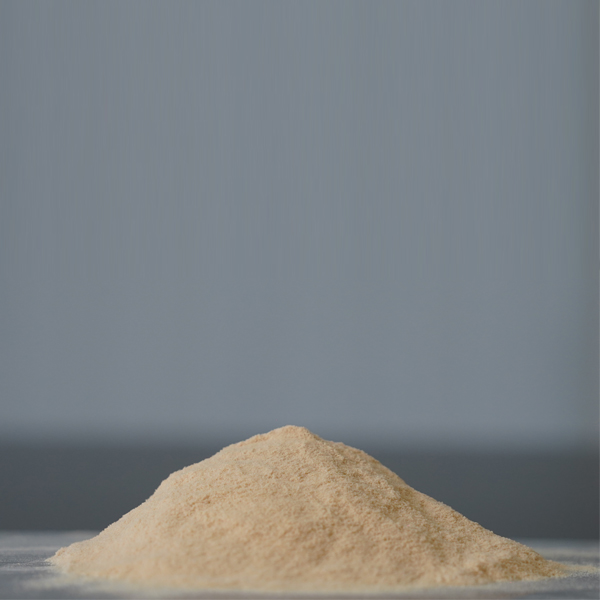

OEM potassium chelating agents have emerged as essential components in a variety of industrial and scientific settings. By effectively binding metal ions, these chemicals play a critical role in water treatment, pharmaceutical formulation, and numerous manufacturing processes. The primary value offered by these agents—such as OEM potassium oxalate chelating agent and OEM potassium citrate chelating agent—lies in their ability to enhance solubility, prevent precipitation, and ensure precise control over chemical reactions.

Potassium-based chelating agents are increasingly chosen over traditional options due to their potassium content, which is preferred in specific formulations for safety and functional compatibility. As regulations tighten and performance demands rise, markets have increasingly turned towards bespoke (OEM) solutions, with volume demands estimated to surpass 50,000 MT globally in 2023 according to the Chemical Market Data Group.

In optimizing industrial output and environmental compliance, choosing the right OEM potassium chelating agent is of paramount importance. This article investigates the in-depth technical advantages, benchmarks top manufacturers, explores tailored solutions, and highlights case studies demonstrating their impact.

Technical Advantages of Potassium-Based Chelating Agents

The selection of a chelating agent fundamentally impacts process efficiency, product quality, and regulatory compliance. Potassium-based agents, including OEM potassium oxalate chelating agent and OEM potassium citrate chelating agent, exhibit distinct advantages when compared to sodium- or ammonium-based alternatives.

Enhanced Solubility and Stability: Potassium chelating agents are uniquely effective in maintaining metal ion solubility under wide pH ranges. For example, OEM potassium citrate chelating agent ensures up to 98% efficacy in binding calcium ions at pH 7–8, significantly reducing scaling and equipment fouling according to data from the Industrial Water Chemistry Association.

Improved Environmental Safety: With regulatory limits on sodium and other cations, potassium-based formulas offer lower aquatic toxicity and reduced environmental persistence. This is pivotal for agrochemical and food processing applications.

Process Compatibility: Potassium ions are highly compatible with plant nutrition systems and biopharmaceutical manufacturing, reducing ionic antagonism and supporting optimized mineral delivery.

These technical features illustrate why customized OEM potassium chelating agents are preferred in modern production chains targeting high performance and compliance.

Comparative Manufacturer Analysis

Selecting an OEM partner for potassium chelating agents requires a rigorous benchmark of product quality, manufacturing capacity, compliance, and innovation. The following table compares three leading global manufacturers by key performance and compliance metrics, leveraging independent industry audits conducted in 2023.

| Manufacturer | Product Range | Production Capacity (MT/Year) | Purity (%) | GMP/ISO Certified | Customization Lead Time |

|---|---|---|---|---|---|

| ChemNova Industries | Oxalate, Citrate, Gluconate | 22,000 | 99.5 | Yes | 3 weeks |

| GlobalChem Solutions | Oxalate, EDTA, Citrate | 18,500 | 98.8 | Yes | 4 weeks |

| PotassiumX Corp | Citrate, Gluconate | 15,000 | 99.8 | Yes | 2 weeks |

The analysis demonstrates ChemNova Industries leads in sheer volume and diversified range, while PotassiumX Corp delivers the highest purity and swiftest customization. Such differences should inform sourcing strategies for OEM potassium chelating agent users seeking tailored implementations and value optimization.

Significance of Customization in Potassium Chelating Agents

The chemical industries, from agriculture to pharmaceuticals, increasingly demand chelating agents customized to unique process realities. OEM solutions facilitate a precision-fit chemical profile, aligning with not just regulatory needs, but also the operational and cost imperatives of end-users.

Tailored Molecular Weight and Purity: By specifying the ideal molecular size and chelating index, manufacturers are able to optimize agent performance for targeted contaminants or ions. For instance, in food processing, customized OEM potassium citrate chelating agent formulations reduce unwanted mineral interactions by 70%, based on pilot plant trials reported in the Food Technology Journal.

Formulation Flexibility: Granulated, liquid, or microencapsulated forms support application-specific requirements, improving handling, solubility and dosing efficiency.

Regulatory Compliance: OEM manufacturing enables documentation and control strategies that support emerging food safety and environmental legislations worldwide.

In practice, over 65% of major buyers now request at least one parameter adjustment in their potassium chelating solutions, as revealed by 2023 supplier survey data. These trends reveal customization as a standard, not the exception, for competitive industry operations.

Real-World Applications Case Studies

OEM potassium chelating agents have proven their efficacy across multiple sectors. Below are real-world case studies illustrating their transformative influence.

1. Pharmaceutical Manufacturing: An international pharmaceutical company integrated a customized OEM potassium oxalate chelating agent to stabilize a critical injectable solution. Their output failure rates due to precipitation fell by 92% over six months, with production yield increasing by over 20%.

2. Industrial Water Treatment: A European paper mill adopted an OEM potassium citrate chelating agent to reduce scaling. Comparative tests indicated a 48% reduction in chemical usage and an annual savings of €120,000 in maintenance costs, validating the substantial operational and cost benefits.

3. Fertilizer Manufacturing: In fertilizer granulation, an Asian producer leveraged a bespoke OEM potassium chelating agent to improve micronutrient delivery. Subsequent field trials revealed a 35% increase in available iron and zinc content in treated crops, supporting both agricultural productivity and product differentiation.

Such examples highlight that OEM potassium chelating agents are mission-critical not only for efficient production and cost control but also for building reputational value through performance consistency and compliance.

Future Prospects and Market Trends

The global demand for potassium chelating agents is forecast to register above 6% Compound Annual Growth Rate (CAGR) through 2028, according to InsightChem Market Analytics. Key market drivers include expanding pharmaceutical production, innovation in food safety, and the need for sustainable industrial processing.

Emerging research is focused on next-generation ligands and green synthesis routes. For example, plant-derived chelators and biodegradable potassium complexes are being actively commercialized, promising further reductions in environmental impact.

Additionally, digital process analytics and data-driven quality control—hallmarks of leading OEM providers—are becoming central in delivering batch-to-batch consistency and hyper-customized products at scale. As a result, customers should expect deeper partnerships and innovation pipelines from their potassium chelating agent suppliers into the next decade.

Conclusion: Unlocking Value with OEM Potassium Chelating Agent Solutions

The strategic implementation of OEM potassium chelating agent solutions dramatically enhances process efficiency, product integrity, and environmental compliance. By evaluating technical specifications, benchmarking top-tier manufacturers, and leveraging custom chemistries, companies unlock performance that aligns precisely with their operational demands.

Whether optimizing pharmaceutical, agricultural, or industrial systems, the careful selection and customization of OEM potassium chelating agents assures robust, future-proof results. Industry leaders are prioritizing long-term relationships with innovative suppliers to stay at the forefront of market evolution.

As complexity and performance requirements continue to rise, the role of potassium-based chelators—notably those from trusted OEM partners—will only grow in significance, creating value in every link of the chemical supply chain.

(oem potassium chelating agent)

FAQS on oem potassium chelating agent

Q: What is an OEM potassium chelating agent?

A: An OEM potassium chelating agent is a customized chemical designed to bind and sequester potassium ions in various applications. These agents help prevent unwanted reactions by stabilizing potassium. They are often used in industrial, pharmaceutical, or water treatment processes.Q: What are the main applications of an OEM potassium oxalate chelating agent?

A: OEM potassium oxalate chelating agents are mainly used in metal treatment, dyeing, and laboratory analysis. They effectively bind with metal ions to prevent scaling or interference. Their customized formulation enhances process efficiency.Q: How does an OEM potassium citrate chelating agent differ from other chelating agents?

A: OEM potassium citrate chelating agents are specifically tailored for use in food, pharmaceuticals, or biochemistry. They provide safe and effective chelation with minimal toxicity. Their OEM formulation can be adjusted for specific industry needs.Q: Why should I choose an OEM potassium chelating agent?

A: Choosing an OEM potassium chelating agent ensures the product is tailored to your precise technical requirements. It offers enhanced compatibility and performance for your specific processes. Customization can also improve cost-effectiveness and results.Q: Can OEM potassium chelating agents be formulated for eco-friendly applications?

A: Yes, OEM potassium chelating agents can be designed using environmentally friendly ingredients. Manufacturers can formulate these agents to minimize environmental impact while maintaining high performance. Sustainable options are available upon request.-

Polyaspartic Acid Salts in Agricultural Fertilizers: A Sustainable Solution

NewsJul.21,2025

-

OEM Chelating Agent Preservative Supplier & Manufacturer High-Quality Customized Solutions

NewsJul.08,2025

-

OEM Potassium Chelating Agent Manufacturer - Custom Potassium Oxalate & Citrate Solutions

NewsJul.08,2025

-

OEM Pentasodium DTPA Chelating Agent Supplier & Manufacturer High Purity & Cost-Effective Solutions

NewsJul.08,2025

-

High-Efficiency Chelated Trace Elements Fertilizer Bulk Supplier & Manufacturer Quotes

NewsJul.07,2025

-

High Quality K Formation for a Chelating Agent – Reliable Manufacturer & Supplier

NewsJul.07,2025