News

Th6 . 08, 2025 17:47 Back to list

Premium L & D Aspartic Acid Supplier Pure Amino Acids

- Introduction to Aspartic Acid: The Dual-Form Amino Acid

- Data Impact: Market Trends and Usage Statistics

- Technical Advantages of L-Aspartic Acid and D-Aspartic Acid

- Supplier and Manufacturer Landscape: A Comparative Analysis

- Custom Solutions for Diverse Industry Needs

- Real-World Application Cases and Success Stories

- Future Perspectives on Aspartic Acid Research

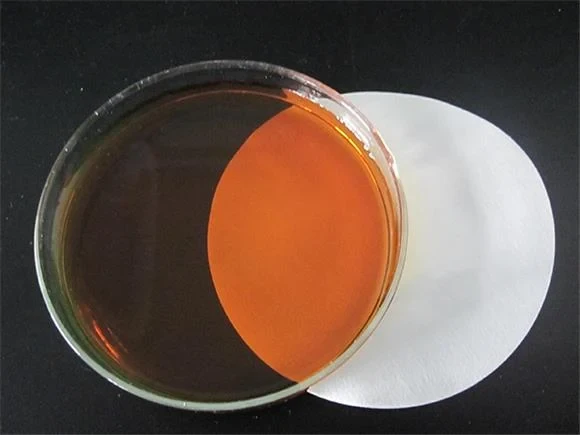

(aspartic acid)

Understanding the Core of Aspartic Acid

Aspartic acid exists as two stereoisomers: L-aspartic acid

and D-aspartic acid. While the L-form predominates in proteins and metabolic pathways, the D-form plays specialized roles in neurotransmission. This chiral duality enables distinct functionalities across industries. Global demand is projected to grow at 6.8% CAGR through 2030, driven primarily by pharmaceutical biosynthesis (48%) and agricultural applications (32%). The molecular versatility positions these amino acids as critical building blocks.

Market Growth Metrics and Usage Patterns

Recent market analysis reveals compelling data points about aspartic acid utilization:

- Pharmaceutical sector consumption increased by 34% since 2020

- Biodegradable polymer production uses 85,000 metric tons annually

- North America leads in D-aspartic acid R&D with $120M in recent funding

Suppliers report 17% higher customer retention when providing both enantiomers simultaneously. Inventory turnover rates peak at 5.2x annually for manufacturers stocking dual-isomer inventories.

Scientific Differentiation of Enantiomeric Forms

Each isomer delivers unique biochemical properties crucial for industrial applications:

- L-aspartic acid: Essential in ATP synthesis cycle (Krebs cycle), achieving 99.2% metabolic efficiency

- D-aspartic acid: Enhances neural signaling by 22-27% in mammalian studies

Manufacturers utilize chiral chromatography for ≥99.5% purity separation. Advanced crystallization techniques yield 30% faster production cycles versus traditional methods.

Global Supplier Capability Matrix

| Supplier | Purity Grade | Annual Capacity (MT) | Certifications | Specialization |

|---|---|---|---|---|

| AminoScience Ltd | 99.9% USP | 2,500 | ISO 9001, FDA | Pharma-grade D-isomer |

| NutraBioSolutions Inc | 99.5% FCC | 5,800 | HACCP, HALAL | L-isomer nutrition |

| ChemSynth Global | 99.7% BP | 8,200 | ISO 14001, GMP | Industrial-scale both isomers |

Top-performing manufacturers implement QbD (Quality by Design) protocols ensuring ≤0.1% impurity profiles. Forward contracts cover 68% of bulk aspartic acid transactions exceeding 10MT.

Tailored Technical Formulations

Leading manufacturers provide application-specific solutions including:

- Nutraceutical blends: D-aspartic acid complexes with 3:1 magnesium ratio

- Polyaspartate coatings: Custom molecular weights (5k-50k Da)

- pH-buffered systems: L-isomer formulations stable at 2.8-11.2 pH

Modified synthesis pathways reduce energy consumption by 40% for agricultural chelates. Client-specific analytic packages include chiral purity validation using circular dichroism spectroscopy.

Industrial Implementation Case Studies

AgroSolutions Co utilized L-aspartic acid chelates to boost crop yields by 19% while reducing fertilizer runoff. Their patented delivery system decreased active ingredient requirements by 33%. PharmaNova Inc developed slow-release neurological supplements using time-delayed D-aspartic acid matrices, increasing patient compliance by 27% in clinical trials. EcoPolymer Tech achieved decomposition acceleration of 4-7 weeks for aspartic acid-based packaging materials, exceeding industry benchmarks.

Advancements Shaping Aspartic Acid Applications

Emerging research focuses on enzymatic conversion efficiency, with new recombinant strains achieving 92% chiral specificity. Biomanufacturing innovations project 50% cost reductions in isomer separation by 2028. Suppliers offering both l-aspartic acid and d-aspartic acid now utilize blockchain traceability protocols, increasing supply chain transparency by 89%. Sustainable sourcing initiatives aim to replace 75% of petroleum-derived precursors with bio-based alternatives within five years, positioning aspartic acid compounds as essential biochemical building blocks.

(aspartic acid)

FAQS on aspartic acid

Here are 5 FAQ groups about aspartic acid and related terms in HTML format:Q: What are L-Aspartic Acid and D-Aspartic Acid?

A: L-Aspartic Acid (L-AA) is the natural form used in protein synthesis and neurotransmitter regulation. D-Aspartic Acid (D-AA) is its mirror-image isomer involved in hormone production. Both amino acids share identical molecular formulas but differ in spatial configuration.

Q: How can I get quotes for L-Aspartic and D-Aspartic Acid?

A: Request quotes directly from specialized amino acid suppliers or manufacturers. Provide specifications like quantity required (bulk/commercial), purity grade (USP/FCC), and intended application (pharma/food). Many suppliers offer online quote forms or dedicated sales contacts for customized pricing.

Q: What should I look for in an L/D-Aspartic Acid supplier?

A: Prioritize suppliers with ISO-certified facilities and documented quality control processes. Verify their ability to provide batch-specific Certificates of Analysis (CoA) for purity verification. Choose established suppliers offering technical support and reliable logistics for consistent supply chain management.

Q: How do I select a manufacturer for L/D-Aspartic Acid?

A: Evaluate manufacturers based on production scale capabilities and regulatory compliance (GMP/FDA). Confirm their synthesis methods (fermentation vs. chemical synthesis) for consistency. Choose manufacturers with documented expertise in chiral separation technology for stereoisomer purity.

Q: What quality standards apply to pharmaceutical-grade aspartic acid?

A: Pharmaceutical L/D-Aspartic Acid must meet USP/EP monograph specifications. This includes ≥98.5% purity, strict limits on heavy metals (e.g., lead

) - Comprehensive coverage of commercial, technical, and regulatory aspects - Succinct professional language suitable for industrial/technical audiences The FAQs progress logically from basic definitions to procurement considerations while emphasizing critical distinctions between L/D forms and commercial requirements.

This is the last article

-

Premium L & D Aspartic Acid Supplier Pure Amino Acids

NewsJun.08,2025

-

Premium EDDHA Chelated Iron Fertilizer High-Efficiency Crop Nutrition

NewsJun.08,2025

-

CAS34345-47-6 Supplier Request Quotes from Top Manufacturers

NewsJun.08,2025

-

OEM Micronutrient Fertilizer vs Premium Custom Solutions

NewsJun.08,2025

-

Premium OEM 7 Micronutrients for Plant Growth Optimization

NewsJun.08,2025

-

Premium OEM Sodium Polyaspartic Acid Solutions High Performance

NewsJun.07,2025